In 2025, A4 thermal paper in Bangladesh has become a crucial item for businesses relying on thermal printers. Prices...

How to Generate Barcode Labels: A Step-by-Step Guide

Barcode labels are an essential tool in modern business practices, helping with inventory management, sales transactions, and product tracking. Whether you're managing a warehouse, running a retail store, or working in manufacturing, generating barcode labels accurately and efficiently is a critical task. Here's a comprehensive guide on how to generate barcode labels, from understanding the different types to printing and applying them.

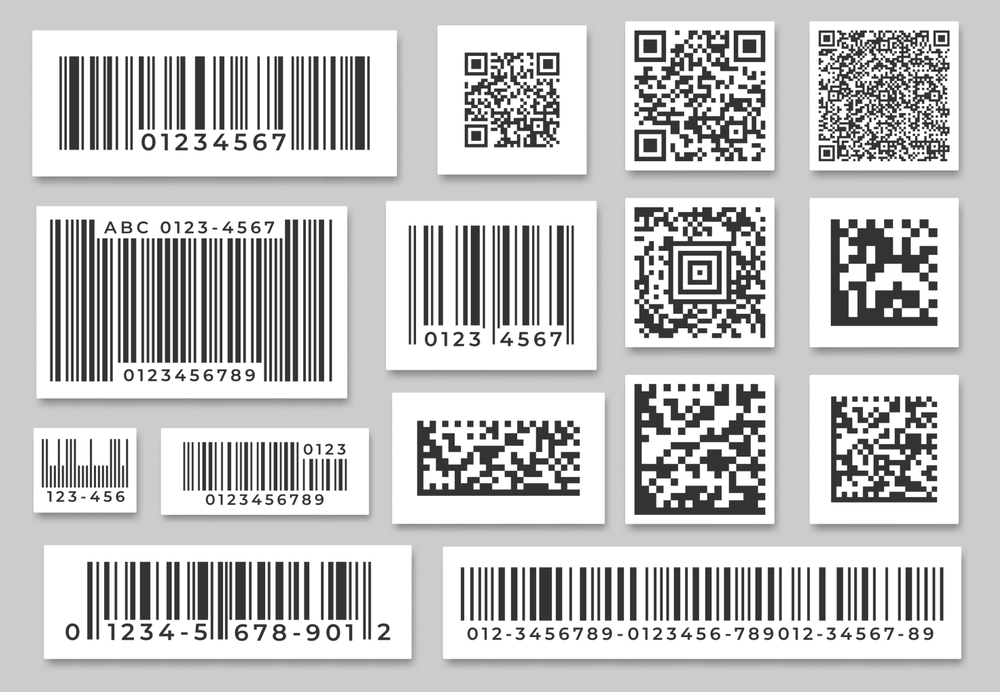

1. Understand the Types of Barcodes

Before you generate barcode labels, it's important to understand the various types available. The most common barcode types include:

-

1D Barcodes: These are the traditional linear barcodes, consisting of parallel lines and spaces. Examples include UPC (Universal Product Code) and EAN (European Article Number).

-

2D Barcodes: These barcodes contain data both horizontally and vertically, allowing more information to be stored in a smaller space. Examples include QR codes and DataMatrix codes.

The type of barcode you need depends on the kind of data you wish to encode and your specific business requirements.

2. Choose the Barcode Format

Once you’ve decided on the barcode type, choose a format that meets your needs. Some of the most popular formats include:

-

UPC-A and UPC-E: These are used mainly in retail for tracking products.

-

EAN-13 and EAN-8: These are used internationally for retail product labeling.

-

Code 128: Ideal for encoding alphanumeric data and used in various industries, including logistics and manufacturing.

-

QR Code: These 2D barcodes can store a large amount of data, including URLs, contact information, and even product details.

Ensure that the format you choose is compatible with the scanner or reader that will be used to interpret the barcode.

3. Select Barcode Generation Software

Generating barcode labels requires the use of specialized software. There are various barcode generation tools available, including free and paid options. Popular choices include:

-

BarTender: A professional tool for creating and printing barcodes. It supports a wide variety of barcode types and integrates with other software for labeling and printing.

-

ZebraDesigner: Zebra Technologies offers this software specifically for creating barcode labels for Zebra printers.

-

Online Barcode Generator: A web-based tool for simple barcode generation.

-

Excel Add-ins: For businesses using Microsoft Excel, barcode add-ins are available that can create barcodes directly within your spreadsheets.

Ensure that the software you select allows you to customize the label size, barcode type, and other important design features.

4. Design Your Barcode Labels

After choosing your software, design the barcode label. Most barcode label design tools come with customizable templates, but it's essential to consider the following elements when creating your design:

-

Barcode Size: Ensure the barcode is large enough for the scanner to read but not so large that it takes up excessive space on the label.

-

Label Size: Choose a label size that fits the application, whether you're labeling small products or larger items.

-

Additional Information: Add relevant product details such as item names, prices, serial numbers, or expiry dates. This can often be done through the software’s text fields.

-

Branding and Aesthetics: Customize the label with your logo, product name, and colors. Ensure the design is professional and legible.

Make sure your barcode and additional text are clear and of adequate resolution to ensure that scanners can read the label without difficulty.

5. Input Data for Barcode Generation

Once the label design is ready, input the data that needs to be encoded in the barcode. This may include:

-

Product ID or SKU number

-

Serial numbers

-

Price

-

Batch number or expiry date

This data can either be manually entered into the barcode software or imported from an external database or spreadsheet, depending on the software you're using. Ensure the accuracy of the data to avoid errors in product identification.

6. Test the Barcode

Before printing large quantities of labels, it’s essential to test the barcode to ensure it scans correctly. Use a barcode scanner to verify that the data is being read accurately.

Many barcode label design tools allow you to test the barcode on-screen before printing. If you’re using an external barcode scanner, you can print a small batch of labels and scan them to confirm readability.

7. Print the Barcode Labels

Once your barcode label design is complete and tested, it's time to print the labels. Depending on your needs, you may want to print the labels in-house or use a third-party printing service.

-

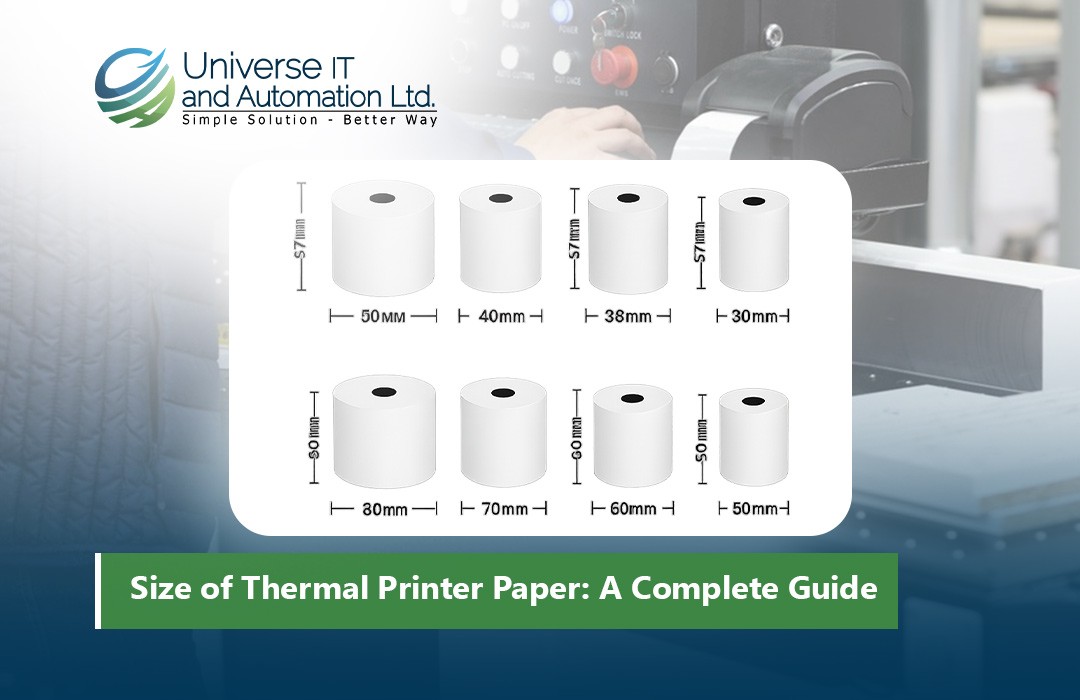

In-house printing: If you’re printing the labels yourself, you’ll need a barcode label printer. Thermal printers, such as direct thermal or thermal transfer printers, are commonly used for barcode printing due to their speed, efficiency, and high-quality output.

-

Outsourcing: If you prefer not to handle the printing process yourself, many companies specialize in printing barcode labels in bulk. These companies can print high-quality labels on various materials, from paper to synthetic materials, to ensure durability.

8. Apply the Labels

After printing your barcode labels, apply them to your products or packaging. Make sure they are positioned in a way that ensures easy scanning, typically on flat surfaces or areas with minimal obstruction. It's also important to ensure that the label is securely attached, especially if the product will undergo rough handling or be exposed to outdoor conditions.

9. Maintain Your Barcode System

Once your barcode labels are in place, it's crucial to maintain your barcode system. Regularly check the barcodes for damage, ensure that scanners are working properly, and update your labeling system as necessary when products change or new items are added to your inventory.

Conclusion

Generating barcode labels is an essential process that helps businesses streamline operations, improve inventory management, and reduce human error. By understanding the types of barcodes, selecting the right software, designing your labels carefully, and ensuring proper printing and application, you can create an effective barcode labeling system that supports your business needs.

Leave a comment