In 2025, A4 thermal paper in Bangladesh has become a crucial item for businesses relying on thermal printers. Prices...

- Home

- Card Printer addremove

- Barcode addremove

- Security & Identity

- CCTV addremove

- Printing addremove

- Drivers & Support

- Blog

All Cattegories

Call us:

01823021975Latest posts

-

A4 Thermal Paper Price in Bangladesh 2025Read more

A4 Thermal Paper Price in Bangladesh 2025Read more -

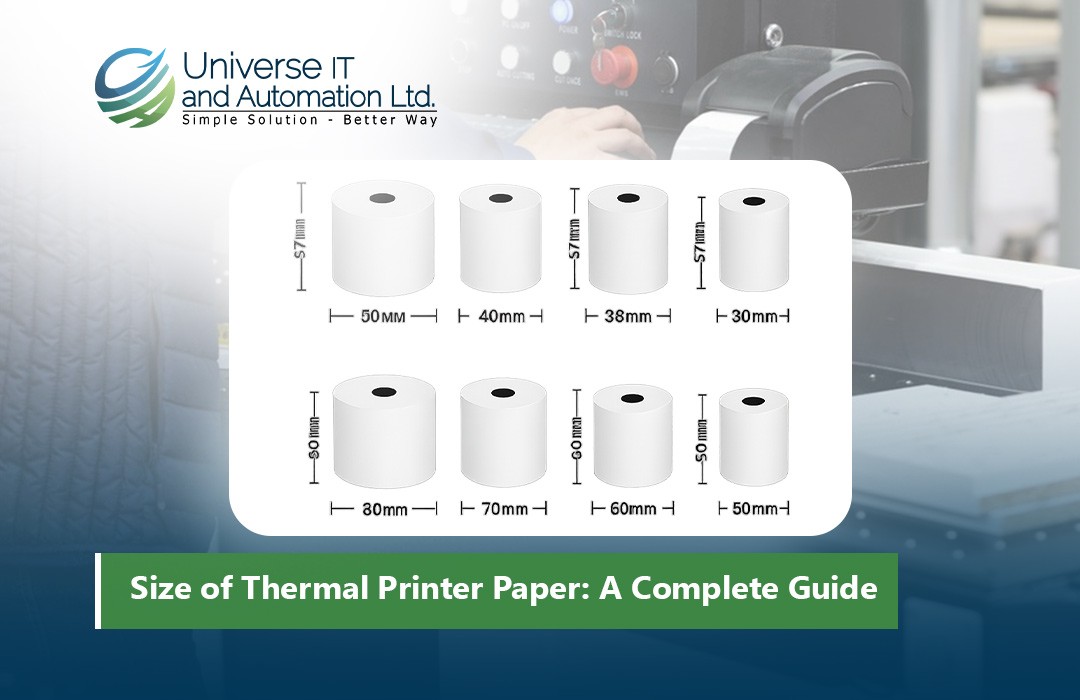

Size of Thermal Printer Paper: A Complete Guide18/08/2025Read more

Size of Thermal Printer Paper: A Complete Guide18/08/2025Read moreDiscover everything you need to know about thermal printer paper sizes in this comprehensive guide. From standard...

-

How to Insert POS Paper in Your Printer18/08/2025Read more

How to Insert POS Paper in Your Printer18/08/2025Read moreLearn how to insert POS paper into your printer quickly and correctly to avoid jams, misprints, or downtime in your...

-

Top 5 Mini Printer Prices in Bangladesh 202518/08/2025Read more

Top 5 Mini Printer Prices in Bangladesh 202518/08/2025Read moreLooking for the best mini printers in Bangladesh for 2025? Our comprehensive guide covers the top 5 mini printers,...

-

How to Choose the Right Size of POS Thermal Paper Rolls02/07/2025Read more

How to Choose the Right Size of POS Thermal Paper Rolls02/07/2025Read moreSelecting the right size of POS thermal paper rolls is a simple yet vital decision for your business operations....

-

Top POS Thermal Paper Brands Trusted by Retailers in 202502/07/2025Read more

Top POS Thermal Paper Brands Trusted by Retailers in 202502/07/2025Read moreSelecting a trusted POS thermal paper brand is more than just buying paper rolls — it’s about ensuring smooth...

-

Top Mistakes to Avoid When Buying a POS Receipt Printer02/07/2025Read more

Top Mistakes to Avoid When Buying a POS Receipt Printer02/07/2025Read moreChoosing the right POS receipt printer is crucial for smooth business operations and a positive customer experience....

-

How to Choose the Best POS Printer for Your Retail Store02/07/2025Read more

How to Choose the Best POS Printer for Your Retail Store02/07/2025Read moreChoosing the right POS printer is crucial for smooth retail operations and a better customer checkout experience....

-

Top 5 POS Printers for Small Businesses in 202502/07/2025Read more

Top 5 POS Printers for Small Businesses in 202502/07/2025Read moreInvesting in the right POS printer can streamline your checkout process and enhance customer satisfaction. The Epson...

-

Best ID Card Printer for Office in 202504/06/2025Read more

Best ID Card Printer for Office in 202504/06/2025Read moreChoosing the right ID card printer boosts your office security and professionalism. The printers listed here are...

Blog categories

Search in blog

How to Print on RFID Cards: A Step-by-Step Guide

RFID (Radio Frequency Identification) cards are widely used for various applications, such as access control, membership identification, contactless payments, and more. Printing on RFID cards can help businesses and individuals customize these cards with logos, identification numbers, and other relevant information. However, printing on RFID cards requires specific equipment, techniques, and care to avoid damaging the embedded RFID chip. Below is a comprehensive guide on how to print on RFID cards.

1. Understand RFID Card Components

Before printing on an RFID card, it's essential to understand the components involved. RFID cards contain a microchip and an antenna embedded inside the plastic. These elements are responsible for transmitting information wirelessly when in proximity to an RFID reader. The printing process must ensure that these components are not damaged while still achieving a high-quality print.

2. Choose the Right RFID Card Printer

To print on RFID cards, you need a specialized printer that supports this type of printing. Regular inkjet printers won't work for RFID cards due to the special nature of the cards and the need for precise printing technology. Here are some common types of printers used for printing RFID cards:

-

Thermal Transfer Printers: These printers use heat to transfer dye onto the surface of the card. They are ideal for printing RFID cards as they can handle high-quality color printing and can apply durable graphics and text.

-

Direct-to-Card Printers: These printers print directly onto the card's surface using heat. They are commonly used for simple designs like text or logos but might not be suitable for highly detailed prints.

-

Re-transfer Printers: A re-transfer printer prints the image onto a transfer film, which is then fused onto the card surface. This method ensures superior print quality, making it ideal for full-color and high-resolution designs.

3. Prepare Your Design

Before printing, prepare your design using graphic design software such as Adobe Photoshop, Illustrator, or dedicated ID card design software. Your design should include:

-

Logo: If you're printing a company logo or any other graphical element, ensure it is high-resolution to avoid pixelation.

-

Text: Include relevant information such as cardholder names, identification numbers, or access codes. Choose fonts that are easy to read.

-

Barcode or QR Code: Many RFID cards incorporate barcodes or QR codes, which can be scanned for additional information.

When designing, make sure that the print area avoids covering or interfering with the RFID chip or antenna location on the card. This will ensure the RFID functionality is not compromised.

4. Load the RFID Cards Into the Printer

Once your design is ready, load the RFID cards into the printer's card feeder. Ensure the cards are oriented correctly, with the RFID chip and antenna properly aligned in relation to the printer's printhead. Be cautious not to damage or bend the cards while handling them.

Most RFID card printers have specific guides to help align the cards correctly and prevent misfeeds. It’s also important to check the printer settings and ensure that the type of card (PVC, composite, etc.) is selected in the printer’s software to ensure optimal print quality.

5. Print the RFID Cards

After setting up your printer and design, initiate the print process. The printer will apply the design onto the RFID cards, usually through a thermal transfer or direct-to-card printing method.

For thermal transfer printing, the printer will use a ribbon to transfer the ink onto the card's surface. This method ensures that the printed design is durable and resistant to wear and tear.

For direct-to-card printing, the printer will use heat to fuse dye onto the card's surface. This method is ideal for simple designs but might not offer the same durability as thermal transfer printing.

6. Check for Quality and Card Functionality

After printing, carefully inspect the printed cards for any imperfections, such as misalignment, smudging, or color inconsistencies. Ensure that the printed information is clear and readable.

It's also important to test the functionality of the RFID chip. Use an RFID reader to scan the card and verify that it works as intended. If the card is not functioning properly, it may be due to improper printing techniques or damage to the chip during the printing process.

7. Post-Printing Processing (Optional)

Once the cards are printed and the design quality is confirmed, you may need to apply additional finishes or protections, depending on the intended use. Some optional processes include:

-

Lamination: Applying a protective laminate layer can enhance the durability of the card, protecting it from wear and tear, scratches, and fading.

-

Encoding: Many RFID cards require specific encoding to store information, such as access rights or payment details. This step can be done after printing using an RFID encoding device or through the printer itself if it supports encoding.

Conclusion

Printing on RFID cards requires careful consideration of the card's components and using the right equipment. By choosing the appropriate printer, preparing your design carefully, and ensuring that the cards are loaded and printed correctly, you can achieve high-quality results while maintaining the integrity of the RFID functionality. With the right tools and attention to detail, you can create professional, customized RFID cards for various applications.

Related posts

-

Want to Buy Zebra ZXP Series 7 Ribbon? Here's What You Need to Know

Posted in: Default category23/06/2024The Zebra ZXP Series 7 ribbon is an essential component for anyone using the Zebra ZXP Series 7 card printer. Whether...Read more

Want to Buy Zebra ZXP Series 7 Ribbon? Here's What You Need to Know

Posted in: Default category23/06/2024The Zebra ZXP Series 7 ribbon is an essential component for anyone using the Zebra ZXP Series 7 card printer. Whether...Read more -

Best ID Card Printer - Best Advice on All Leading Brands

Posted in: Default category02/07/20245 Best ID Card Printers in 2024 When you dive into the world of ID card printers, you'll find a plethora of options...Read more

Best ID Card Printer - Best Advice on All Leading Brands

Posted in: Default category02/07/20245 Best ID Card Printers in 2024 When you dive into the world of ID card printers, you'll find a plethora of options...Read more -

Best Selling ID Card Ribbon & Accessories

Posted in: Default category02/07/2024When it comes to ID card ribbon and supplies, it's essential to choose reliable products that ensure crisp, clear...Read more

Best Selling ID Card Ribbon & Accessories

Posted in: Default category02/07/2024When it comes to ID card ribbon and supplies, it's essential to choose reliable products that ensure crisp, clear...Read more -

Employee ID Card Printer at Best Price In Bangladesh

Posted in: Default category02/07/2024Top Employee ID Card Printers in Bangladesh for 2024 1. Evolis Primacy 2 The Evolis Primacy 2 is highly regarded...Read more

Employee ID Card Printer at Best Price In Bangladesh

Posted in: Default category02/07/2024Top Employee ID Card Printers in Bangladesh for 2024 1. Evolis Primacy 2 The Evolis Primacy 2 is highly regarded...Read more -

Best Retransfer ID Card Printer : Top Printers Chosen By Experts

Posted in: Default category06/08/2024Retransfer ID Card Printer Fargo HDP6600XE ID Card Printer Evolis Primacy 2 Expert Printer Zebra ZXP Series 9...Read more

Best Retransfer ID Card Printer : Top Printers Chosen By Experts

Posted in: Default category06/08/2024Retransfer ID Card Printer Fargo HDP6600XE ID Card Printer Evolis Primacy 2 Expert Printer Zebra ZXP Series 9...Read more

Leave a comment